Pallet Forks vs. Buckets: Which Is the Best Worksite Attachment

Skid steer loaders might be not the most powerful machines on the market. One of their greatest strengths, however, is the fact that they can be adapted to different tasks by an extensive choice of attachments. Among the most common are pallet forks and buckets.

Working in a warehouse, construction site, or farm, and thinking about major differences, advantages, and best applications of pallet forks and buckets just shows that you want to be productive, safe, and efficient in your trades. In fact, you will gain the power of making such decisions that lead to higher productivity, safety, and efficiency.

As most of the readers of https://steerskid.com/ are people who are involved in such works and thus would like to know which attachment of the two is the best for a skid steer in a jobsite or warehouse, this article will be about that and more.

Understanding Pallet Fork and Bucket

- What Are Pallet Forks?

Pallet forks mainly serve the purpose of changing a skid steer into a forklift that can handle heavy lifting of a stack of goods. Powered by two metal tines, pallet forks are inserted under pallets or any kind of stacked materials to lift and relocate them. They are indispensable when it comes to the movement of palletized goods, timber, crates, and other kinds of heavy and voluminous items in a fast and accurate manner.

- What Are Buckets?

Buckets are the most common and universally used skid steer attachments. They can be of several types, for instance, smooth buckets, rock buckets, and grapple buckets. The primary function of buckets is to do work such as scooping, digging, loading, levelling, and transporting loose materials that may be soil, gravel, mulch, or debris.

Key Differences Between Pallet Forks and Buckets

| Feature | Pallet Forks | Buckets |

| Primary Function | Lifting and transporting palletized and large bulky items | Scooping, digging, and moving loose materials |

| Design | Two adjustable steel tines on a frame | Large, curved, open container |

| Typical Uses | Warehousing, material handling, loading/unloading | Construction, landscaping, excavation, grading |

| Material Handling | Solid objects and palletized goods | Loose soil, gravel, mulch, debris |

| Load Visibility | High operator visibility to see the load | Limited visibility due to bucket front |

| Weight Capacity | Load depends on tine strength and skid steer ROC | Volume-based; varies with bucket size and loader strength |

Choosing the Right Attachment for Your Needs

When to Choose Pallet Forks?

A heavy work routine of handling palletized goods, building materials, or any other type of loads that need careful placement will make pallet forks an obvious option of highest efficiently.

- Fast palletizing of metal, wooden carriages, and heavy equipment either in warehouses or on job sites.

- Great for farms, landscaping, and construction that require accurate and tight stacking.

- The flexibility of the adjustable tine makes the size of the load indeterminable.

- In comparison to buckets, pallet forks not only reshape but do so without any damage.

When to Choose Buckets?

Nothing can match a bucket when it comes to excavation, grading, and material loading in areas where there are only loose materials.

- Scooping and transportation of soil, sand, gravel, or mulch can be done effectively by buckets.

- They are versatile for use as digging, backfilling, leveling, and removing waste from the site.

- Preparation of building sites, landscaping, and road repairs are the most suitable uses of them.

- Also, the rock bucket or the grapple bucket can be used for certain materials and tasks.

Versatility and Efficiency Considerations

Pallet Forks Efficiency

- Facilitate rapid load/unload cycles thus boosting jobsite organization.

- Lift the level of safety by cutting down on manual handling.

- It is possible to use the adjustable spacing of forks to handle different pallet sizes and odd loads.

- Different models have different fork lengths and capacities; the length is usually between 36 and 48 inches.

Bucket Efficiency

- Can handle larger volumes of loose material per load than forks.

- There are different bucket types for different uses: smooth, multi-purpose, grapple, rock.

- The use of hydraulic grapple arms on buckets offers versatility for grabbing irregular materials.

- There can be different widths of a bucket depending on the loader, commonly from 48 to 84 inches.

Maintenance and Compatibility Tips

Pallet Forks

- Four tines must be of sufficient thickness and the frame strong enough to match the ROC (Rated Operating Capacity) of the skid steer.

- A good practice is to verify that the forks are fabricated from hardening steel so that they become more resistant to wearing and bending.

- It is advisable to ensure that the quick-attach mounting systems you use are of the same type and that the unit is firmly joined.

- Inspection for tine damage should be a regular activity and forks should be kept in a clean condition.

Buckets

- First of all, the bucket size should be compatible with the weight and hydraulic capacity of your skid steer.

- For example, in the case of a hydraulic (grapple) bucket, make sure your loader’s hydraulic flow meets the requirements.

- To help keep the performance of the digging operation, replace the cutting edges so that the bucket edge is in good condition.

- Take measures to ensure the cleanliness of the material to prevent it from building up and thus affecting the function.

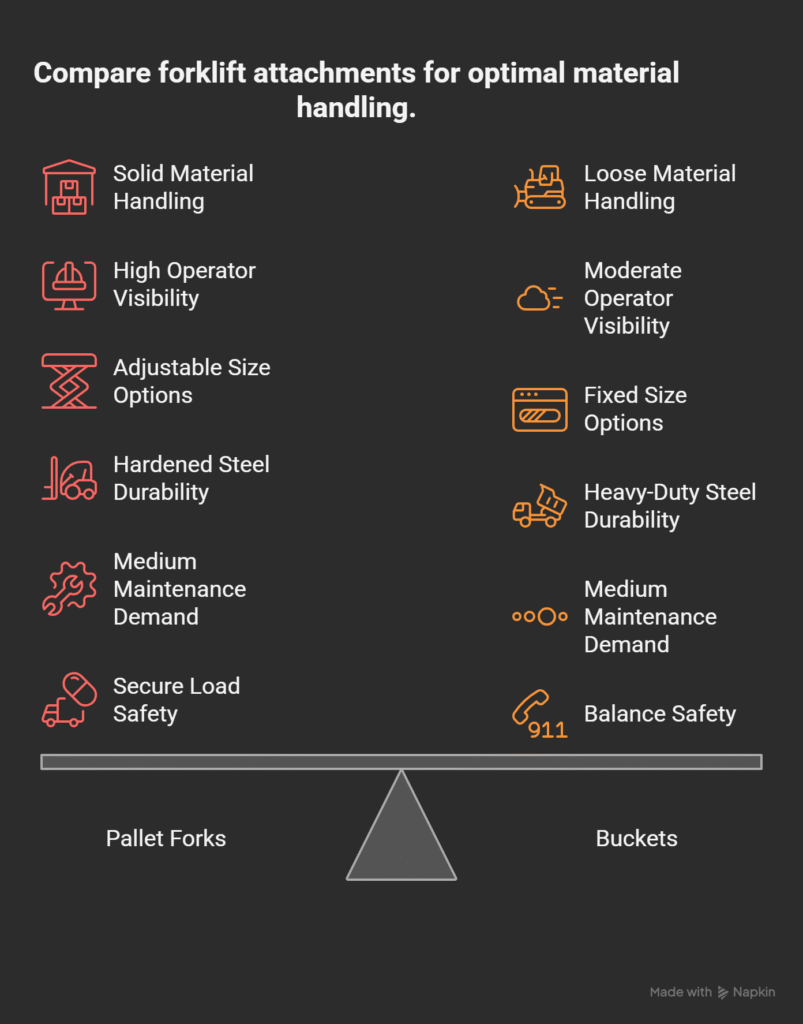

Comparative Summary Table Pallet Forks vs Buckets:

| Aspect | Pallet Forks | Buckets |

| Ideal For | Palletized goods, crates, lumber | Loose materials, digging, grading |

| Material Type | Solid, fibrous, bulky loads | Soil, gravel, mulch, debris |

| Operator Visibility | High – precise load placement possible | Moderate – limited when full |

| Size Adjustability | Adjustable tines, variable spacing | Fixed width, different bucket sizes |

| Durability | Hardened steel options available | Heavy-duty steel, replaceable edges |

| Maintenance Demand | Medium – tine inspections, rust prevention | Medium – edge wear, hydraulic system checks |

| Safety Considerations | Secure heavy loads; avoid tipping risks | Maintain machine balance to avoid tipping |

Three Bullet Points on Practical Benefits

- Precision and Safety: Pallet forks provide the best visibility of the load and control, thus the risk of accidental drops is reduced to a minimum together with site safety is improved.

- Material Handling Speed: Buckets are very good at moving large quantities of loose materials quickly thus the operation time during excavation or clean-up is greatly reduced.

- Versatility Through Attachment Mix: Skid steer operators are highly benefitted by having both these attachments and thus the decision of which one to use depends on task demands can be made quickly.

FAQs About Pallet Forks and Buckets Attachments

What size pallet forks should I choose for my skid steer?

Fork length and capacity should be chosen depending on the rated operating capacity of the skid steer and the size of the loads that are typical. The most common sizes are 36–48 inches for the length; capacity to handle anywhere from 2,000 to 3,000 lbs or more depending on what you need.

Can pallet forks and buckets be used interchangeably on the same skid steer?

Most skid steers are equipped with a universal SSQA system that enables quick changes of the fork and bucket attachments. So, the answer is yes.

Are pallet forks suitable for uneven terrain?

Floating tine pallet forks have the ability to move somewhat laterally, which facilitates the handling of uneven loads or ground conditions in a safe manner.

What types of buckets are available for skid steer loaders?

The options are smooth buckets for general purposes, rock buckets for debris, grapple buckets for grabbing irregular materials, and multi-purpose buckets combining scoop and grab functionalities.

How often should I inspect and maintain pallet forks and buckets?

Frequent and thorough inspection of the attachments before use coupled with periodic cleaning and maintenance (e.g., tine straightening, edge replacement) ensure safety and efficiency of them.

Which attachment is best for warehouse applications?

Typically, pallet forks would be the most suitable in warehouses and logistics environments due to their capability to efficiently lift and move palletized goods.

How do I choose the right bucket size for my skid steer?

Taking into account the capacity requirements, hydraulic limits of the loader, and site constraints will guide you to the right decision; smaller buckets give you more control in tight areas, while bigger buckets will allow you to move more material in one pass.

Conclusion: Choose Wisely Between Pallet Forks Vs Bucket Attachment to Task

The choice between the use of pallet forks or a bucket depends on the kind of a warehouse or jobsite that one has. Indispensable for material handling and the precise movements of loads, pallet forks are just the right tool for warehouses and construction sites that deal with palletized materials.

On the other hand, buckets are the most versatile tool that one can have when it comes to excavation, grading, and any loose substance handling. Most of the time, the smartest decision is to have both of the attachments on your skid steer and then just swap them in and out as the job progresses to get the highest productivity and safety levels.

By knowing the strong points as well as the weaknesses of each attachment, you can decide wisely when buying and running operations which will bring about efficiency, safety, and a return on investment of your skid steer loader.

Ronbuzz is kind of my guilty pleasure. It’s just a simple site with some quick games, but it’s good for killing time. Take a look if you’re bored: ronbuzz

Thanks for sharing. I read many of your blog posts, cool, your blog is very good. https://www.binance.info/register?ref=IXBIAFVY

https://t.me/s/ef_beef

https://t.me/s/officials_pokerdom/4085