TYPHON Skid Steer Snow Blower: Transform your commercial snow removal!

For any professional controlling a fleet of equipment—whether a municipality, a large-scale property management company, or a commercial snow removal contractor—the winter season is a time when the operational efficiency is the key to profit and reputation.

Typically, heavy snow is handled by angle plows, snow pushers, and even manual shoveling. However, these methods struggle when there is heavy accumulation, dense, compacted material, or the common windrows left by city plows. Essentially, these traditional methods are inefficient because they only relocate the problem; they do not solve it.

Consequently, enormous snow piles that take up parking and storage space, need secondary handling or expensive removal by dump truck, and slow down the clearing process become the result. Every minute wasted on struggling with underpowered tools or making multiple passes is a direct reduction of your profit.

The answer of the professionals is a piece of work which is single-mindedly focused on maximum throughput and single-pass efficiency: the TYPHON Skid Steer Snow Blower. This is not merely an instrument; it is a corporate asset intended to change the raw hydraulic power of your compact loader into a force that is unstoppable and does the processing and expelling of the snow in a single continuous, rapid motion.

The Cost of Inefficiency: Moving Beyond Traditional Snow Removal

It is the ultimate tool for any operator who is serious about maximizing the potential of their equipment and cutting down the required man-hours by a huge factor. When you switch from the slow, back-and-forth plowing to the fast, controlled blowing, you completely change the economics of your whole winter operation.

- Plowing creates secondary problems: Although it is fast at the beginning, plowing leads to huge snowbanks that have to be taken care of (stacking, hauling, or melting), and thus the overall project completion time gets longer.

- Manual labor is unsustainable and costly: Using shoveling for walkways and places where it is hard to access is a slow process, it costs money, and it results in high labor costs and increased risk of injury.

- Blades struggle with density: Normal plows and buckets are not able to function effectively with heavily compacted, wet, or frozen snow, and thus they often slow down the skid steer and at the same time increase fuel consumption and drivetrain strain.

TYPHON Engineering: The Power of Direct-Drive Hydraulics

Among the features of the TYPHON Skid Steer Snow Blower that enable it to outrun its rivals are its sturdy build, and its unwavering focus on hydraulic efficiency. It is a unit of the commercial series, designed and built from scratch for long and heavy-duty use, it also perfectly fits with the modern skid steers having a high flow auxiliary system. The main concept that makes the TYPHON an outstanding performer is its solid direct-drive hydraulic system. In contrast to many traditional blowers that use belts, chains, and fragile shear pins, the TYPHON powers the auger and impeller directly from the hydraulic motor.

This design solution is very important for the longest machine availability and the lowest service level in the most difficult situations. With the elimination of belts and chains comes the elimination of the problem of slippage, breakage, and the need to constantly adjust tension, while the absence of external shear pins means that there are no more frustrating cold-weather repairs.

The TYPHON machine features a very efficient two-stage design, which is imperative for dealing with the large volume of snow in an efficient way. The first stage is a heavy metal, probably serrated, helical auger. This element aggressively goes into the snowbank, and it chops and breaks up even the densest, most compacted material, pulling it inward.

The second stage is a dynamically balanced, high-capacity impeller (fan) that catches the pulverized snow and accelerates it at tremendous speed, launching it through the output chute. This coupled two-stage operation is what makes the machine able to keep up with the fast clearing and not to choke even when it is driven into deep, wet drifts-a place where the failure of most attachments is known.

The whole structure is made of high-yield, heavily reinforced steel, and coated with a commercial-grade, corrosion-resistant coating to keep it safe from salt, ice, and wear and tear for a long time.

- Zero Downtime from Shear Pins: The sophisticated direct-drive system makes use of integrated hydraulic pressure relief as its safety mechanism, thus it can recover from radicals very quickly and without hard-to-reach location-targeted manual cold-weather shear pin changing.

- Maximum Torque Transfer: The use of direct power transfer is what makes sure that one hundred percent of a skid steer’s hydraulic output is converted into the action of cutting and throwing, thus a very good performance is possible even under conditions of heavy snow.

- Industrial-Grade Build Quality: The sturdy steel construction of the auger housing, fan housing, and frame gives sufficient support to the whole structure, thus it can meet the challenges of being in continuous contact with frozen snow, ice chunks, and inevitably some pieces of debris.

TYPHON Snow Blower: Core Performance Features

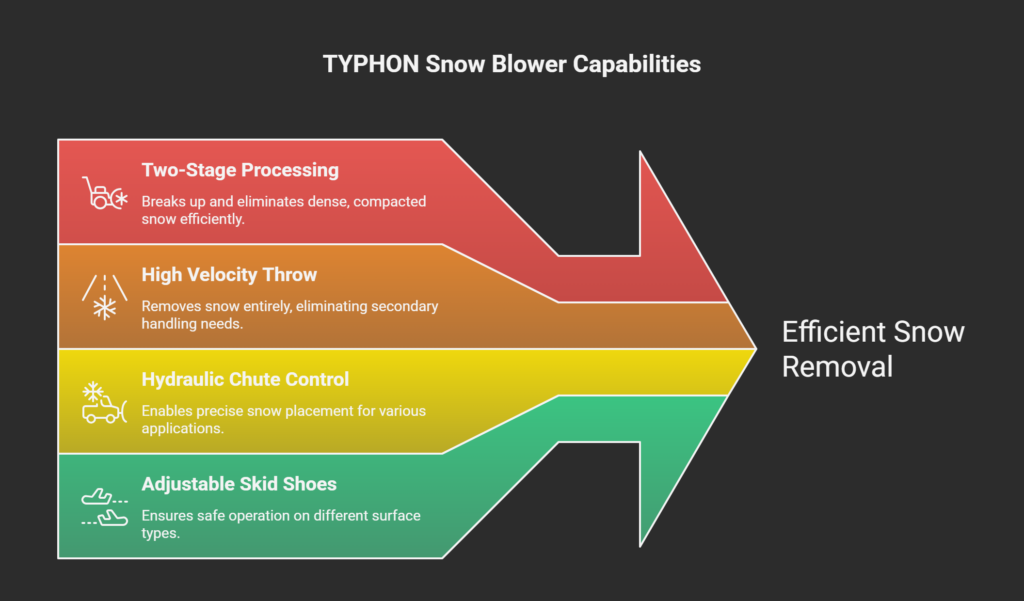

| TYPHON Snow Blower: Core Performance Features | Advantage Over Plowing |

| Two-Stage Processing | Breaks up and eliminates dense, compacted snow that plows struggle with. |

| High Velocity Throw | Removes snow entirely from the area, eliminating secondary stacking/hauling needs. |

| Hydraulic Chute Control | Allows for precise snow placement (loading trucks, clearing near buildings). |

| Adjustable Skid Shoes | Permits safe operation on variable surfaces (pavement, gravel, decorative stone). |

Performance that Delivers: Throwing Distance and Clearing Speed

For professional snow contractors, performance is best understood in measurable terms: how fast can the job be done, and how thoroughly can the snow be removed? The TYPHON Skid Steer Snow Blower is a leader in both measures, and its throwing capacity is mainly responsible for that.

Thanks to the efficient utilization of the high flow rate of the skid steer, the huge impeller can throw snow at a distance which is over 40, 50, or even 60 feet in most cases. This extraordinary throwing range is a real difference-maker as it allows operators to clear the whole parking lots, broad municipal roads, or extensive property boundaries without stacking the snow nearby or requiring a secondary machine for removal even once. This single-pass clearing ability is a great time saver.

Moreover, TYPHON’s high intake capability is very important for keeping the forward speed fast. In many cases, the intake can be as high as 36 inches on a high-flow model, thus the attachment can go directly into very high drifts and the large windrows made by municipal street plows.

Unlike a plow that has to gradually chip away at these obstacles, or a normal bucket which needs repetitive lifting and dumping, TYPHON is doing the material continuously, thus it guarantees a high clearing rate (square footage per hour). The operator can keep the speed constant and thus the work will be done faster and more professionally. The precise control over the hydraulically rotating chute and deflector which is done from the warm cab ensures that the snow is directed exactly where you want it.

This feature is very important when you work close to buildings, landscaping, or adjacent properties and that is why TYPHON is the most suitable Heavy-Duty Snow Clearing attachment.

- Eliminate Secondary Handling: The very long throw distance is what makes it possible for the snow to be cast far away from the working area, thus there is no need for loaders and dump trucks to remove the accumulated piles.

- Conquer Deep Drifts: Powerful auger torque and industry-leading intake height help to ensure that the machine remains in operation even when the snow is deep, heavy, and already packed.

- Precision and Protection: Adjustable, wear-resistant skid shoes (usually made from polymer or heavy steel) assist the operator in lifting the cutting edge just enough in order to protect the surface underneath e.g. pavers, asphalt, or gravel from damage.

The Strategic ROI: Saving Labor, Fuel, and Time

The choice of a TYPHON Skid Steer Snow Blower is a calculated business investment that brings a lot of returns through the improvement of efficiency and the increase of billable capacity. The time saved on the job site is directly translated into the reduction of operational costs and the possibility of taking on more client properties during one single storm event, thus the profit is maximized during the winter season peak.

Imagine the labor savings: what is a task for multiple employees with walk-behind blowers or a single operator struggling with a plow and an hour of stacking that can be done by one skid steer operator using the TYPHON in a very short time. The reduction of man-hours is the most immediate and significant advantage.

Apart from labor, the TYPHON’s smooth running leads to less fuel consumption and machine wear. Rather than repeatedly overloading a skid steer’s engine and drivetrain by pushing it through heavy snow with a plow, the fluid and continuous hydraulic action of the blower is simply more machine-friendly.

A large part of the time when the clearing speed is kept rather than accelerated and braking also lessens the engine and fuel consumption. Besides that, the direct-drive system’s inherent reliability is a great assurance of the maximum machine availability. When a really bad snow storm hits, contractors are in no position to accept a mechanical failure; hence, the TYPHON design is what keeps commercial snow removal services going 24/7. In this way of combining speed, dependability, and less operational stress, TYPHON becomes an indispensable winter fleet optimization tool and a quick Return On Investment mechanism.

- Maximize Billable Hours: By drastically cutting down the time spent on each property, the contractors will be able to work for a greater number of clients during a single storm, thus their revenue will increase directly.

- Reduce Equipment Strain: The blower’s smooth, high-capacity performance is much kinder than the skid steer’s engine, transmission, and hydraulic system could take under the constant heavy plowing shock load scenario.

- Consolidate Equipment Needs: The blower has the capacity to clear large lots, access roads, and small paths thus the demand for walk-behind blowers or the sidewalk sweepers that are specially designed for this purpose can be decreased or even eliminated.

Matching Power: Standard vs. High-Flow Hydraulic Requirements

In order for the TYPHON to perform at the highest level it was designed for, it is extremely important to properly match the

- Standard Flow Models: They are made for machines which usually output 15–25 GPM. Such models are perfect for daily work on small commercial properties, long residential driveways, and are already a great upgrade over plowing when it comes to density handling and throw distance.

- High Flow Models: They are made for machines that can output 30–45+ GPM. These models let the TYPHON work at its full capacity, using the specially designed high-displacement motors to run the huge impellers at full speed and maximum torque. It is necessary to do so if a contractor is working on very deep drifts that need to be cleared quickly, heavy lake-effect snow, or large-scale municipal contracts where maximum clearing speed is the main concern.

The use of a standard-flow machine to operate a high-flow blow will give a disappointing result (throwing distance will be low and stalling will be easy). At the same time, incorrect matching between a machine and an attachment may lead to component damages. Find out about your skid steer’s capabilities or TYPHON’s technical documents before making a decision regarding flow so that you get the most performance out of your Skid Steer Snow Blower.

- GPM is the Critical Metric: The rate at which hydraulic fluid is delivered to the auger is the determining factor for the speed of the auger and the velocity of the impeller, thus it has a direct effect on the cutting power and throwing distance of the blower.

- The Right Motor for the Right Flow: TYPHON creates specific hydraulic motor configurations for standard and high-flow carrier machines to ensure peak efficiency and component longevity.

- Consult Before Purchasing: Correct matching of machine and attachment is essential for performance and component life maximization and ROI enhancement, thus it should be done before purchasing.

The Final Verdict: Mastering the Winter Season

The TYPHON Skid Steer Snow Blower can be considered as the ultimate solution for the problems related to snow. It is at the forefront of heavy-duty, commercial-grade snow management technology. There are no power combinations of plows and buckets that can match the brute-force power, zero-downtime reliability, and precision control this system provides.

By investing in the TYPHON system, you are giving your operation a strategic advantage—the ability to clear properties faster, more thoroughly, and with much less labor and machine strain. Do not spend time pushing and piling the snow, remove it instead.

Carry out your winter season in the most profitable and efficient way by resorting to the definitive Skid Steer Attachments solution for snow removal. Get in touch with the experts at https://steerskid.com/ to select the optimal TYPHON model for your machine’s hydraulic capabilities and prepare to experience true winter mastery.

FAQs – Skid Steer Snow Blower Attachments for Commercial Snow Removal

Does a skid steer snow blower damage gravel or unpaved surfaces?

The blower has to be a heavy-duty, two-stage one with adjustable skid shoes. The operator may adjust the height of the cutting edge 1/2 to 1 inch above the gravel by using skid shoes. Thus, the attachment and the neighboring property are protected by preventing the auger from digging up and throwing stones.

What is the GPM required to operate a professional snow blower?

The requirements are very different. 15–25 GPM is typical for standard flow models. For the best performance, throw distance, and cutting power on large commercial machines like the High Flow TYPHON, a High Flow skid steer with 30 GPM or more is required. Always check the attachment specifications and the machine hydraulic output before making your decision.

Should I buy a snow blower if I already have a strong snow pusher?

They have different functions. Pushers are good for fast, light-to-moderate snow removal on flat terrain where there is enough space for piling. To carry out the complete Commercial Snow Removal, a blower is necessary to remove thick, dense snow, clean where there is no space for piling, load snow onto trucks, or clear sensitive areas.

Why are two-stage snow blowers better?

The two-stage method is better at dealing with thick snow. The first thing the auger does is cutting, breaking up, and feeding the snow, while the second one is the impeller/fan which accelerates and throws it. By doing so, the method reduces clogging, increases throughput, and enhances throwing distance as compared to single-stage machines.

How do direct-drive snow blowers protect themselves without the need for shear pins?

TYPHON direct-drive systems have integrated hydraulic components such as pressure relief valves. Once the auger hits something solid and immovable, the hydraulic pressure goes up and the relief valve changes the flow, thus saving the system without breaking a pin. The operator moves backwards, the system resets, and downtime is avoided.

How wide should my skid steer snow blower be?

The cutting width of the blower should be a few inches wider on each side than the widest part of your skid steer (including tires or tracks). This is done so that the machine won’t be able to travel over, and thus compact, the snow before the blower can treat it, by clearing a wider route.

Can skid steer snow blowers be used to load dump trucks with high sides?

That is one of the advantages of a high-performance hydraulic snow blower attachment. The strong throw and the adjustable, high-