Auger Bits for Skid Steers: Sand, Stumps, and Clay Work Efficiency!

Looking for auger bits for skid steers? It’s a significant decision that impacts how well, how safely, and how long your equipment will last. If you are figuring out the best way to operate on a sandy construction site, getting rid of that pine stump, or dealing with the heavy clay pack, your choice of the bit can turn the day into a highly productive session or quite the costly breakdown.

At SteerSkid, we specialize in offering high-performance attachments that allow your skid steer to work in many ways. This guide shares some professional tips about different soil types and the usage of the correct auger bits for skid steers that will have your capital working for you.

Mastering Sand: Techniques for Loose Soil Stability

When drilling sand, you face the challenge that it is very easy to cut through the material, but practically difficult to take the sand out of the hole. Since sand particles do not stick together, the sand that you have drilled out will often fall back as soon as you pull the bit out. The solution is to get auger bits for skid steers with the right flight design to the application.

- High-flighting bits: Go for double flight augers which offer more surface area to carry the loose sand upwards without the sand falling back down between the flights.

- RPM control: If you run the auger bit very fast in sand, it can “spin”, that is, the bit just throws the material to the sides instead of lifting it. Thus, keep the speed steady and at a moderate level.

- Check the moisture: When sand is just a little damp, the drilling is easier than when it is very dry, the reason being that water makes the particles temporarily stick, thus the hole is less likely to collapse.

Table: Skid Steer Soil Types

| Soil Characteristic | Recommended Bit Type | Tooth Configuration |

| Loose/Dry Sand | Standard Duty Double Flight | Standard Dirt Teeth |

| Damp/Compacted Sand | Heavy-Duty Earth Bit | Hard-Faced Chisel Teeth |

Conquering Clay: Overcoming Suction and Density

In the world of materials, clay is hands down the worst enemy of the operator. Being heavy and as if glue-like, it creates such a “suction” effect that it can freeze your hydraulic motor or if lucky, it will just trap your auger bits for skid steers buried deep. The secret of success in clay lies in achieving aggressive cutting along with fast clearing of the bit.

- Choose Aggressive Teeth: Choosing aggressive teeth most suited for your purposes. Use “wisdom” or chisel-style teeth that have been pitched at a gentler angle to effectively cut through the rubbery clay.

- Do not overload: Drilling the entire depth in one go was never advised. Drill 12–18 inches, pull the bit to remove the clay “plug” and then go back down.

- Planetary drive benefit: When heavy clay is your regular working material, a planetary drive-equipped skid steer is the one to get because it delivers the necessary torque to break the suction.

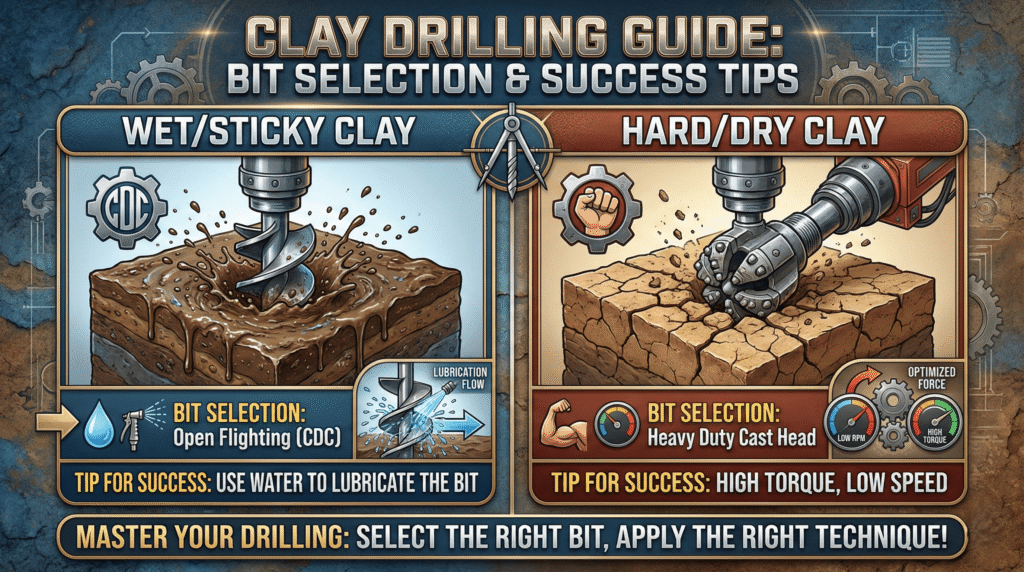

| Clay Type | Bit Selection | Tip for Success |

| Wet/Sticky Clay | Open Flighting (CDC) | Use water to lubricate the bit |

| Hard/Dry Clay | Heavy Duty Cast Head | High torque, low speed |

Stump Removal: Transforming Augers into Planers

Regular auger bits for skid steers are made to move dirt around and not to cut through trees. In the using dirt bit for the stump drilling, you will most probably end up with a broken tooth or bent shaft. But to remove a stump you can always have specialist attachments or rock bits that are designed for high torque.

- Go for a stump planer: This is a specialized bit that uses flat blades to shave the stump down layer by layer, thus turning the wood into mulch instead of trying to “dig” it out.

- Ensure the pilot bit is in the middle: Confirm that the pilot bit is well engaged in the middle of the stump so that the auger does not walk or skid across the surface.

- Watch for stones: The root ball of the stump may have stones in it. Carbide-tipped teeth are a good choice when you are not sure from where the next rock will come.

Choosing the Right Drive: Torque vs. Speed

The effectiveness of your auger bits for skid steers greatly depends on the drive unit that powers them. It is extremely important to match your hydraulic flow with the drive to avoid overheating and to make sure that the bit still has “bite.”

- Planetary drives: These drives are the most reliable methods of soil penetration especially when it comes to hard work such as breaking clay, removing tree stumps and handling rocks.

- Chain Drives: These kind of drives use chains to transfer power, thus they cannot deliver high torque. This becomes an issue when the soil is heavy. Therefore, chain drive is a good choice for landscaping and light soil that has a high sand content.

- Direct drives: Because they allow high-speed drilling in soft loam or sand, direct drives will be the best choice. However, they do not have the necessary “grunt” for industrial applications.”

Maintenance Tips for Longevity

Your auger bits for skid steers are consumables, but with proper care, their life can be extended for years. An efficient bit puts less strain on the hydraulic system thereby less fuel consumption and less wear and tear on the machine.

- Teeth Inspection Daily: Do not operate with chipped or rounded teeth. Lack of teeth gradually letting the boring head wear which is far more expensive down the road.

- After Use Cleaning: Material caking, especially in clay or wet sand, if left untreated will cause rust and corrosion. Flighting remains smooth for the next job if there is a quick wash-down.

- Fasteners Check: The vibration effect of drilling is strong enough to make loose the screws that are holding the teeth or the pilot bit. Prevention of component loss down a deep hole calls for daily tightening.

Table: Skid Steer Components

| Component | Maintenance Frequency | Action Required |

| Teeth | Every 8 hours | Inspect for wear/chips |

| Pilot Bit | Weekly | Check for straightness |

| Output Shaft | Every 40 hours | Grease and inspect for cracks |

Strategic Depth: Using Extensions Safely

Sometimes, the standard 4-foot length of auger bits for skid steers isn’t enough. Extensions give the necessary reach for utility poles or deep foundations, but they change the drill physics.

- Length Restriction: Only use the absolute minimum amount of extension necessary. The longer the bit, the more leverage will be exerted on the mounting plate of your skid steer.

- Vertical Alignment: Make sure that the machine is level always. What seems like a small tilt on the surface turns out to be a big deviation when you are 8 feet down.

- Hydraulic Capacity: The deeper the hole, the greater is the friction. Make sure that your GPM (Gallons Per Minute) is enough to continue the rotation at depth.

FAQs: Skid Steer Auger Bits

What is the best auger bit for heavy clay?

The best bit to use on heavy clay is an Aggressive Duty Double-Flight (CDC). The pointer here is that these bits come with a cast steel boring head whose teeth are angled aggressively in order to make it easier to cut through the density of clay while at the same time the double flighting works to efficiently lift the sticky material out of the hole.

Can I use a dirt auger bit to remove tree stumps?

A dirt bit is a no-go when it comes to tree stumps because it is very likely that the bit will be damaged. Another reason for that is the fact that a standard dirt bit is not meant to break wood. Normally, a Stump Planer is the best option for the job because it can efficiently shave wood into chips by using special blades and high torque.

How do I stop my auger from getting stuck in the ground?

The best way to prevent your auger from sticking, especially when dealing with clay, is to abandon the idea of drilling to the full depth with one pass. Instead use the “pecking” method, i.e. drill a bit, lift to clear the dirt, and continue. Make sure your skid steer hydraulic pressure (PSI) is right for the type of soil you are dealing with too.

What size auger bit do I need for a 4×4 fence post?

A 4×4 post will require an auger bit whose diameter is 9 inches or 10 inches. This will be sufficient enough to cover the fence post plus several inches of concrete or backfill that will give a firm and durable foundation to the fence.

What is the difference between a 2” hex and a 2-9/16” round drive?

The reason why the 2” hex drive is found in most commercial applications is because its hexagonal shape helps to prevent the bit from slipping in the collar while the 2-9/16” round drive is typical of older or light-duty machines.

How often should I replace my auger teeth?

When teeth start to lose their sharpness, or if they have been worn too much, it is time that you replace them. By the way, drilling speed can be decreased by almost 50% simply by drilling with dull teeth besides, even the auger drive motor can suffer massive strain when using blunt teeth.

Do I need a high-flow skid steer to run an auger?

Actually, no. The majority of conventional auger drives work efficiently at a flow between 10 and 25 GPM. In any case, a high-flow system will be required if one is to use very big bits whose diameter is over 30 inches or drill into solid rock.