Mini skidsteer have changed the way in which small and medium size construction and landscaping projects are made. In essence, these are small, compact and handy machines designed to use their power and versatility for a number of different works even in a narrow place. One of the features that makes this possible is the large number of attachments which are available.

Mini skid steer attachments give operators the ability to convert one machine into a multi-functional tool that can access, dig, grade, lift, and haul as required. The facility not only enhances the work but also reduces the number of equipment that is needed to be used which is a very convenient solution for contractors and landscapers in terms of cost.

If talked about, the significance of mini-skid attachments will still be leading on the list. They not only make landscapes, construction, or agricultural work easier for the operators but also help them to complete a variety of jobs in no time.

An appropriate attachment can very effectively maximize the potential of a mini skid steer making it the first choice for the performance of specialist tasks that are not available with the help of other machinery.

With the increasing demand for efficient and versatile equipment, the knowledge of various types of attachments and their specific uses will be the deciding factor for any person who has a mini skid steer and wants to use it to the fullest.

Key Takeaways

- Mini skidsteer attachments are versatile tools that can be used for various tasks such as digging, lifting, and moving materials.

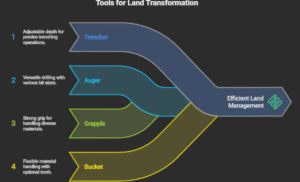

- Mini skidsteer attachments exist in a whole range of different types, such as buckets, forks, augers, and trenchers, each with specific features for particular tasks.

- The use of mini skidsteer attachments may lead to a rise in the efficiency, productivity, and safety of job sites, which makes them a precious investment for construction and landscaping businesses.

- While selecting the proper mini skidsteer attachment, it is crucial that one consider the aspects like the nature of the task, compatibility of the machine, and quality of the attachment.

- In order to operate mini skidsteer attachments in a safe manner, operators are required to take a training course, do inspections of the attachments frequently, and follow the directions of the manufacturers with regard to the operation and maintenance of the equipment.

Types of Mini Skidsteer Attachments

The number of spurious mini skid steer attachments is so large that it covers wide-ranging applications. A bucket attachment is one of the most frequent types, available in different sizes and shapes.

Besides standard buckets which are perfect for general digging and handling of materials; there are also, for instance, trenching buckets or grapple buckets, which are hollowing or grasping of irregular-shaped materials, respectively.

Landscaping, construction, and even farming sectors, are the most common places where the use of bucket attachments is not only allowed but also necessary as they can be employed to renovate gardens or change the nature of the soil if you are an agriculturist. Augers and post hole diggers are one of the next famous groups of attachments.

These groundbreaking tools become quite helpful for the task of setting poles in the ground, or planting trees, the point being that the holes have to be dug in the exactly right spot if the above-mentioned tasks have to be performed. In order for the operators to pick the proper diameter and length for their project, these machines are made with different sizes.

Moreover, the existence of tillers and soil cultivators from which farmers can benefit by transforming land into arable soil through the use of tillers to break hard soil and mix it with organic matter. In these types of usages, the soil health-oriented applications in the gardening and agricultural sectors rely heavily on such attachments.

Benefits of Using Mini Skidsteer Attachments

Utilization of mini skid steer attachments is not limited to only one or two benefits but in fact it can greatly increase the operational efficiency that results in numerous benefits.

The main benefit that goes first on the list is improved productivity. When a mini skid steer is upgraded with the suitable attachment, the operators can finish their works faster than when done using hand tools or less specialized machines.

In support of this, using a hydraulic grapple makes the work of loading and unloading materials as fast as possible thereby the time taken in these works is minimal and workers may use the remaining time to perform more work.

Another advantage is that by using mini skid steer attachments the money can be used more efficiently. Rather than buying different types of machines for diverse kinds of jobs, the operator can purchase one mini skid steer and as many attachments as he wants that will be capable of doing different jobs.

Not only does this save money, but it also reduces maintenance, and storage costs are also lower. Moreover, the time saved from changing the attachment also means that the operators can change the condition of the job site without any significant downtime, thus they will always be productive.

How to Choose the Right Mini Skidsteer Attachment

Picking the most suitable mini skidsteer attachment will be influenced by many factors. Performing with the machine must be the first point to consider.

For instance, regularly working in a landscaping company that frequently plants trees or installs fences, then the investment of an auger attachment is undoubtedly helpful. On the contrary, material handling or grading with the bucket and grading blade may be more suitable as well as more beneficial.

One of the most important aspects to be considered is a mini skid steer model that is compatible. As a result, a great number of attachments designed for a specific make and model of the skid steer should be checked for compatibility with the particular machine.

In this regard, the operator weighing capacity and hydraulic capacities of both the attachment and the skid steer help in the formation of the best decision on whether it is achieved and the vehicle remains safe and reliable.

When talking to the manufacturers and dealers, you get the chance to know about products, their features and the work for which they are best suited.

Tips for Using Mini Skidsteer Attachments Safely

When mini skidsteers and their attachments are running, the first and foremost thing on the list should be safety. One basic yet very important tip is to carry out an extensive pre-operation inspection on the machine as well as the attachment.

This must include the search for any damages or worn-out clothing parts, the checking of security on all hydraulic connections, and the verification of the proper functioning of safety features.

Besides this, operators should also acquaint themselves with the different and specific use of nature of each attachment as they may have their own safety considerations.

Part of the safety measures is also the issue of proper training. Operators should be equipped with the necessary and adequate training on the effective use of mini skid steers and their attachments. Among the subjects covered should be the understanding of load limits, the ability to spot hazards in the work area, as well as the practice of safe maneuver and movement.

Furthermore, the wearing of proper personal protective equipment (PPE) such as hard hats, gloves, and steel-toed boots can go a long way to lessening the risks connected with operating heavy machinery.

Maintenance and Care for Mini Skidsteer Attachments

Maintenance on a regular basis is the most important thing to keep mini skid steer attachments in good working condition and for a long time to come. Operators must come up with a maintenance program that requires cleaning the attachments after each job to eliminate the dirt, dust and corrosive materials which may cause the metal to rust and thus damage the machines in the future.

Part of the task of checking al sting is the detection of any leaks in the hoses as well wear; this should also apply to hydraulic hoses, any signs of deterioration should be taken care of immediately so that the operations will not fail. Lubrication is just as important but there should not be a neglect of it.

The majority of the attachments have parts that move and these need to be regularly lubricated not to mention that the performance should be smooth and efficient as well.

The operators should refer to the manufacturer’s guidelines for the specific lubrication intervals and recommend the products. Again, when confirming that the attachment is not being used, a proper storage facility—preferably in a dry place—may be an ideal way of keeping it safe from hostile yet neutral surroundings.

Innovative Mini Skidsteer Attachments on the Market

The demand for mini skid steer attachments is a stream of improvisations that include even the minutest technological advancement. While one way to notice such a change is by looking at the development of multitools to combine more than one function into a single implementation, nothing exemplifies this trend better than just that.

For instance, some companies provide tools that can reconfigure a bucket, grapple, and auger job within seconds, so operators can become immediately compatible with modified job requirements without needing a separate instrument.

Another promising feature is the application of smart technology in mini-skid steer attachments. A few contemporary products are embedded with sensors that monitor and report performance-related statistics like load weight or hydraulic pressure in real-time.

This information is very instrumental to operators as it helps them not only work safely but also efficiently. Moreover, technical improments of the materials have contributed to the production of the light but still strong and durable skid steer attachments which in return don’t slow down the overall machine performance.

Maximizing Efficiency with Mini Skidsteer Attachments

To sum up, the use of mini skid steer attachments is an ideal way of upgrading these small machines from standard to versatile and efficient tools in almost any application.

For this reason, it is crucial to invest in proper research on the various attachments available and their appropriate usage to let operators pick the right tools for the job according to the needs of their projects. Convenience is just the tip of the iceberg when we talk about the advantages provided by these attachments, as they take a large share of productivity and savings economy as well.

The speed with which technology moves makes it essential to know about the latest gadget that may come in handy in the field, your operational strategies can be boosted.

Following all safety regulations and providing the correct training and maintenance conditions, operators will definitely be allowed to hit the full potential of the mini skid steers while avoiding abuse and accidents.

By the end of it all, the decision to purchase and install quality mini skid steer attachments raves up your efficiency, maintains productivity and guarantees you a win not only for your project but also in the long run.

Very clean website , thankyou for this post.

I’ve recently started a website, the info you provide on this website has helped me greatly. Thank you for all of your time & work. “If you see a snake, just kill it. Don’t appoint a committee on snakes.” by H. Ross Perot.

I’m not that much of a online reader to be honest but your blogs really nice, keep it up! I’ll go ahead and bookmark your site to come back in the future. Cheers

Usually I don’t read article on blogs, but I would like to say that this write-up very forced me to try and do so! Your writing style has been amazed me. Thanks, quite nice post.

https://t.me/s/officials_pokerdom/3145