Skid steers are the compact, highly maneuverable machines that have a very wide range of applications in the construction industry and, hence, have become the ‘must-have’ through their ability to turn 90 degrees in place by their unique wheeled or tracked design.

This feature makes them perfect for working in narrow spaces that other bigger ones cannot go or operate efficiently. One can hardly believe the power that is working for them, and hence their weight is very modest. In this way, they engage in various tasks like digging and ground leveling, material lifting and loading, and many other jobs.

They can better perform their duties on a not-so-level surface, which further boosts their use, thus giving them jobs in all different conditions on the construction site.

The versatility of skid steers mainly comes down to their compatibility with an extensive range of attachments. With these attachments, a skid steer can become a one-stop tool for performing the tasks of digging, lifting, snow removal, etc.

As an example, dirt removal can be carried out with a bucket, and at the same time, a pallet fork can facilitate the movement of heavy materials. Moreover, instruments like the auger and the trencher that are purposely made for certain jobs can be like drilling holes for fence posts or making trenches for utility lines.

Such capabilities have made skid steers the indispensable assets of contractors who are always seeking to keep the organized flow of work on their sites and their productivity at full swing.

Key Takeaways

- One construction skid steer is a machine with great flexibility which is capable of handling different jobs such as excavation, grading, and material handling, etc.

- The first step of choosing the right attachments for the skid steer is to analyze and understand the needs of the job. For example, in the case of handling large volumes of loose materials, a general-purpose bucket would be the proper choice. On the other hand, if the work is required to be done with precision in a form of digging or trenching, then an auger or trencher will do the job better. Consequently, comprehending the details of each attachment’s potential to result in a better working solution for the skid steer can be a huge advantage.

- Regular maintenance and proper care for the machine, which should also include routine checks and servicing, are the basics that guarantee a machine’s good performance and its long life.

- The best and most important practice of ensuring safety while operating the skid steer would be to train the operators thoroughly. This training procedure markedly reduces the chances of accidents caused by operators’ inattentiveness or lack of knowledge.

- Hardwares like GPS and telematics can be a part of the solution that overall makes the operations better and more productive.

Proper maintenance and care for optimal performance

A skid steer needs regular maintenance in order to stay at its full working capacity for a long time. This comprises checking the consumption of fluids such as engine oil, hydraulic fluid, and coolant, as well as inspecting filters and belts for wear through.

A properly serviced machine not only has better performance but also has a longer period of function, thus, the need for expensive repairs or replacements is minimized. The operator should always adhere to the manufacturer’s maintenance schedule which usually specifies oil changing, filter replacements, and other major services intervals.

Operators are additionally responsible for daily pre-operation inspections prior to a skid steer usage. This is looking over any parts of the machine where damage or wear may be visible, making sure all safety features are functional, and all the controls are in the right working order.

Reacting to a problem when it is still small and not waiting for a staff issue is, therefore, both time and money-wise a great solution. Besides that, the machine needs to be cleaned and kept free of any debris which in turn gives better visibility to the operator and helps in the removal of lessor wear in parts of the machine.

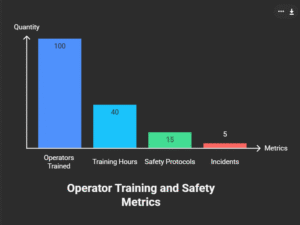

The safe operation of a skid steer should be at the heart of measures to avoid accidents and create a positive working atmosphere. A thorough and complete operator training should be mandated to the facilitators of the machine to acquaint them with how the controls function, the capabilities of the machine, and the safety features of it.

This training should be on the operation of the skid steer as well as a skill to detect hazards in the working area. For instance, an operator should be proficient enough to detect that a heavy object is falling, the floor is not steady, or something in the environment that could cause a hazard during operation.

Moreover, along with first training, lifelong education is a must in safety retaining. Continuous practice in safety between staff can help remind of a better practice and keep the operators updated of the safety rules or the equipment.

During the training part of putting on safety equipment (PPE) stress should also be there; the operator must know that he should be wearing a hard hat, gloves, and the like while working at heavy machinery.

Employers who build safety and responsibility among the workers are able to see a drastic decline in the number of accidents and the injuries on the work sites.

Utilizing advanced technology for improved efficiency

The presence of highly developed technologies within the area of skid steer has changed the management and implementation of construction projects to a great extent. These days the telematics system is often fitted into the modernized skid steers.

The telematics system allows the collection of data in real-time about performance, fuel consumption, and maintenance. Through this data, the operator and fleet manager can decide when to operate, allocate the rest periods, and do the maintenance work which will result in less time spent on the machine and more work done.

Moreover, by upgrading in automation, a technological change has brought about such a feature as the automatic grade control and precision guidance systems.

By exactly counterchecking the feedback on the performance and adjustment of machine positioning, these pieces of technology are helping the operators to get instruments set right thereby performing tasks like grading and excavation to dating accurate-perfecters.

The example of an automatic grade control system being used in grading to level off a site is one that reworks are moved to minimum thus the project doesn’t get delayed as it stays on schedule.

Taking advantage of the above technological improvements, construction companies can thus raise productivity levels while at the same time they can reduce labor costs.

Implementing strategic workflow and scheduling

The efficient management of workflow is very important to achieve maximum productivity in the places where skid steer machines are used during the construction process.

Workflow that has been well planned ensures that the jobs are sequenced in a logical manner which means that the time used for waiting between two operations is minimized. For example, a schedule that puts excavation works before concrete pouring can be the perfect one allowing a neat change of construction phases.

By carefully reviewing deadlines for various projects and establishing the interrelations between different tasks, project managers will be able to come up with schedules that would ensure the best use of equipment and the right allocation of the workforce.

Besides that, the use of project management software can be instrumental in not only the scheduling but also in the communication among team members.

This software makes it easy for project managers to give assignments taking into consideration the availability of the crew as well as the readiness of the equipment, at the same time, they can be up to date with the progress of the work through the real-time updates.

Through open communication and making sure that all team members are aware of their responsibilities, construction companies can relegate the postponements which are caused by poor communication or non-coordination.

Streamlining material handling and transportation

Material handling that is efficient is the prime factor in construction projects where everything is measured in terms of time. The role of skid steers in such a situation cannot be exaggerated; they make it possible for the materials to be transported quickly over the job sites.

To make this process more efficient we need to set up material movement routes that are well thought of, free of traffic, and safe for the other equipment and personnel who may be moving around. Routes that are clearly marked can contribute to preventing accidents which in turn will improve, though a little, the efficiency of the workflow at a large scale.

Apart from that, the utilization of some attachments such as pallet forks or material buckets not only makes it easier for the skid steer to load and unload various materials but also makes it possible to do so in the safest way.

For instance, when bricks or tiles are to be transported in the form of pallets, the use of pallet forks is the most suitable way as it makes the process of loading and unloading quick and at the same time there is no damage to the materials

The execution of a material handling plan creates a win-win situation as it not only quickens the operations but also reduces labor costs since there are fewer manual work tasks such as lifting and carrying

Evaluating and optimizing job site layout for maximum productivity

The construction of a job site should impact positively on a job which is the purpose of a construction project involving skid steer. The layout that is optimized takes care of the following; the location of the equipment, the areas that are used for the storage of the material, the routes that both machines and personnel use for accessing the place.

By the use of the equipment that has been strategically positioned near to the place where it is going to be used most, the teams in construction can save the time of the journey between the tasks and hence increase the overall efficiency.

Moreover, the layout of the site may also be working efficiently by having these activities – loading of materials for the different categories and the release of the already completed works – carried out in their respective zones.

This means that the organization causes less confusion among workers and assures that everyone undoubtedly knows the locations of the tools and materials whenever they need them.

The process of assessing job site layouts during the whole project cycle, in fact, is a way of placing the eye on the different areas that need further developing.

The adjustments may be required when the work progresses or when new challenges have been encountered. Through the prioritizing of the efficient job site layout, the companies operating in the construction sector can thus make use of the maximum productivity, at the same time saving the minimal amount of the workers’ hours and resources wasted.

Definitely believe that which you stated. Your favorite reason seemed to be on the internet the simplest thing to be aware of. I say to you, I certainly get irked while people consider worries that they just do not know about. You managed to hit the nail upon the top as well as defined out the whole thing without having side effect , people could take a signal. Will probably be back to get more. Thanks

You are my intake, I own few web logs and often run out from to brand.

Hiya, I’m really glad I’ve found this information. Today bloggers publish just about gossips and internet and this is actually annoying. A good website with exciting content, this is what I need. Thanks for keeping this web site, I’ll be visiting it. Do you do newsletters? Can’t find it.

Thanks for some other informative web site. Where else may I get that type of information written in such a perfect way? I’ve a venture that I am just now running on, and I’ve been on the look out for such information.

https://t.me/officials_pokerdom/3445