When to Replace Your Skid Steer Engine Parts: Expert Timing Tips

The skid steer machine is the undisputed workhorse of any construction or landscaping fleet. Its versatility is almost a legend, but that versatility is completely dependent on the skid steer engine health. A skid steer with worn-out internal components is not only inefficient, but it is also a time bomb.

The most expensive maintenance strategy in the heavy machinery world is the “waiting for it to break” mentality. To keep your machine performing at the best level, you need to perceive the subtle (or not so subtle) signs of a replacement requirement of your skid steer engine parts.

Why Regular Skid Steer Engine Check-Up is Crucial?

Performing preventive maintenance can save you from being inconvenienced by a minor repair that takes just an afternoon and a whole month of lost revenue. The engine of your machine is such a finely tuned system that any failure of a part, e.g., a clogged fuel injector or an old piston ring, can cause the entire system to become over-stressed.

If you run your skid steer engine even after it starts giving you symptoms, you are heading towards getting a complete engine failure which means paying three to four times the amount of a parts replacement done on time.

- Reduce the time your machine is out of service: By recognizing the signs of wear early, you can plan for the repairs to be done during your off-peak hours instead of having the breakdown occurring right in the middle of the job that has been ordered as your top priority.

- Keep the resale value as high as possible: The market value of your skid steer can be drastically increased if you have a good record of timely parts replacement.

- Fuel savings: When you put in new engine parts, especially injectors and filters, the combustion process will remain efficient which will result in lower fuel consumption on a daily basis.

Major Signals That Your Skid Steer Engine Is Running On Empty

Usually, the engine gives out various signals to the operator of the machine before it totally goes dead. The first thing to do in expert timing is to understand these clues.

Excessive smoke, odd vibrations, or a drastically reduced hydraulic lift power can usually be linked to the engine running low on torque.

- Exhaust color signals: Black smoke is a sign of the fuel system problem while blue smoke is the result of oil burning (piston rings). Besides, white smoke is a sign of a coolant leak (head gasket).

- Strange sounds: The knocking or pinging sound is mainly due to the worn out bearings or timing problems and immediate check-up is needed.

- Starting trouble: The ignition will be difficult even with a good battery if the problem is low compression or glow plugs are going bad.

A Guide to Changing Skid Steer Engine Parts

Every manufacturer has manuals, but the actual working conditions (such as dust, heat, heavy weights) tend to force the equipment owners to change the engine parts more frequently.

Following is a list of the routine engine component replacement periods for you to consider as a preventive measure against failure.

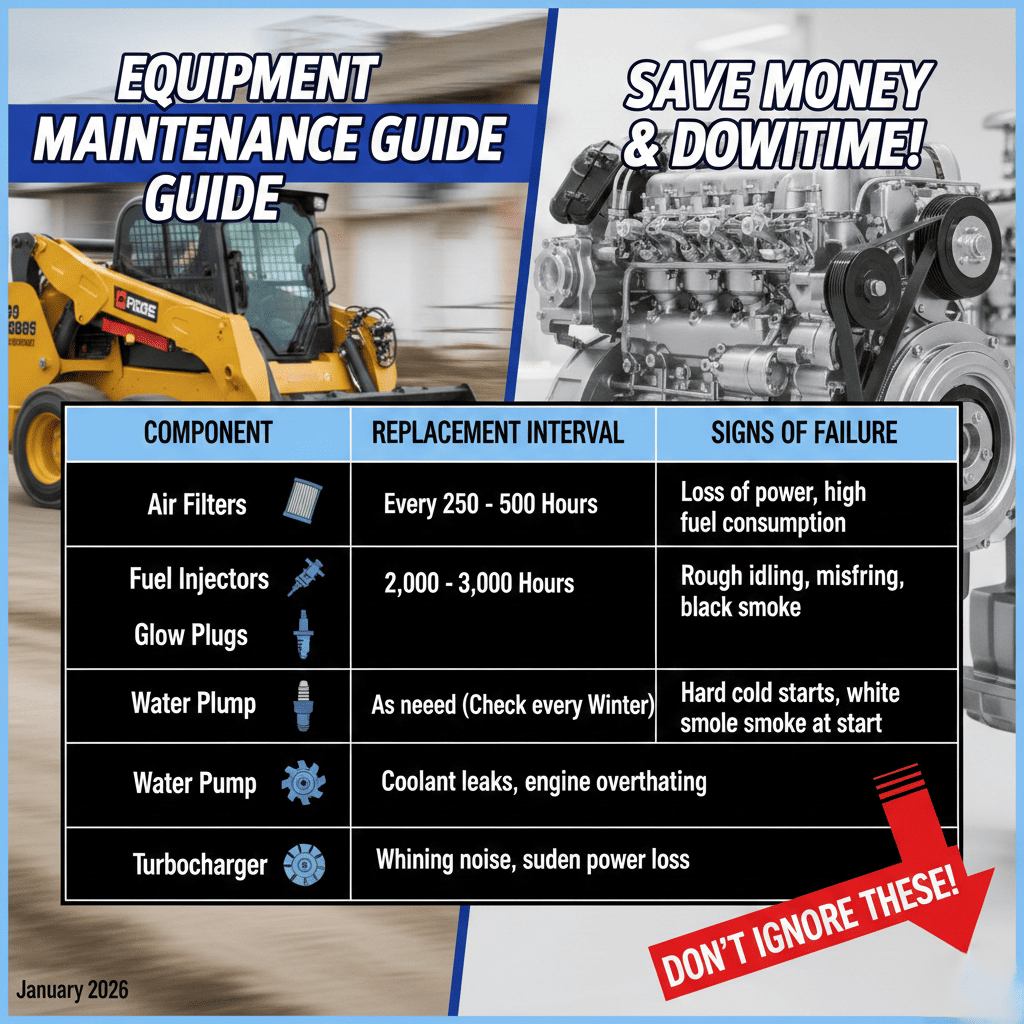

| Component | Standard Replacement Window | Signs of Failure |

| Air Filters | Every 250 – 500 Hours | Loss of power, high fuel consumption |

| Fuel Injectors | 2,000 – 3,000 Hours | Rough idling, misfiring, black smoke |

| Glow Plugs | As needed (Check every Winter) | Hard cold starts, white smoke at start |

| Water Pump | 2,500 – 4,000 Hours | Coolant leaks, engine overheating |

| Turbocharger | 5,000+ Hours | Whining noise, sudden power loss |

- Filter care: It is a must to always change both primary and secondary air filters at the same time so that no dirt can get into the combustion chamber.

- Cooling system: Every 500 hours, check if there are any “soft spots” or cracks in the hoses. An overheated engine because of a hose that burst due to a crack can happen within minutes.

- Drive belts: Replace them if you find glazing or fraying since a snapped belt will stop alternators and cooling fans immediately.

Cylinder and Piston Wear – a Troublesome Combination

The main components of your machine that provide power are cylinders. With the passage of time and running for thousands of hours, the rubbing of piston rings with the cylinder walls builds up gradually “blow-by,” i.e., the combustion gases escaping to the crankcase. In turn your machine loses horsepower.

Look around for the oil that may have leaked into the air intake or if the oil pressure has dropped considerably; this is the time to consider purchasing an engine rebuild kit.

- Compression Test: Check the compression with the help of this test every 1,000 hours to have somewhat of a breakdown of the internal condition of cylinders.

- Oil Testing: The references to metal particles that can only be seen under the microscope during scheduled oil sampling (SOS) are therefore pointing to bearing and piston wear.

- Checking Gaskets: When “weeping” of the oil around the head gasket is noticed, it is very important to replace it without delay so that the cylinder heads do not warp.

Fuel System Plays a Decisive Role in Engine Life

Currently, skid steers employ high-pressure single rail (HPCR) technology. These systems provide phenomenal efficiency while their parts have a high degree of sensitivity to impurities.

Similarly, a single tank load of bad diesel could easily result in injector destruction. The most important aspect of modern engine life being how long it will last is the proper timing of your fuel system maintenance.

- Water Separators: Remove the water separator daily. Water presence in the fuel system is a major cause of rusting inside the injector tips.

- Injectors Timing: The injectors may be partially blocked or worn out if the engine “hunts” (the engine speed fluctuates) when idling.

- Quality of the Fuel Pump: Putting off the replacement of the pump will result in getting stuck, exactly when you least want to. A whining pump is a warning that it’s going to fail very soon.

Better Parts Selection for a Longer Engine Life

The quality of the parts used determines how soon you will return to the workshop for a part of the same type when it comes to replacement. Taking advantage of high-quality aftermarket or OEM-spec components from reliable sources like SteerSkid will guarantee that the tolerances fit your engine precisely.

Parts made by cheap, off-brand manufacturers are usually the cause of the fast wearing out of other components indirectly related.

- Precision Engineering: Verify that the weight and balance of the replacement pistons and bearings conform to the OEM standards exactly.

- Resistance to Heat: Consider using gaskets and seals made from high-temp Viton or equivalent materials since skid steers usually have cramped, hot engine bays.

- Warranty Is Important: Get your parts from sources that offer a compatibility guarantee in order to avoid costly returns and downtime lasting longer than expected.

FAQs – Skid Steer Engine

How long can a skid steer engine be used?

Depending on intensive maintenance, the majority of the diesel skid steer engines may operate for about 5,000 to 8,000 hours. Some models are known to last for 10,000 hours before a complete overhaul if the owners take great care and carry out timely parts replacement such as injectors and turbochargers.

What is a failing skid steer turbo about?

Troubles signs are a very high-pitched whistle or a whining sound, the power or boost loss is very noticeable, and there is too much blue or black exhaust smoke. You have oil in the turbo housing if the turbo seals have been broken.

Why does my skid steer gradually lose power under load?

The power loss can be linked to the restricted fuel that is resulting from clogged filters or blocked air intakes or even worn out fuel injectors. The engine may be producing the sound as if it were healthy but no “grunt” from the engine that is the indication to check the hydrometrics, as the pump may be overloading the engine.

How often should I change the oil in my skid steer?

Despite many manufacturers advocate 500 hours, professionals in the industry suggest changing engine oil and filters every 250 hours, particularly if the machine is working in dusty areas or under the influence of extreme temperatures.

Can I replace one fuel injector only, or do I have to replace all of them?

You may only replace one injector if you want to, but in practice, it is recommended to change the whole set. You will have one injector at the end of its lifecycle if it is time to replace it, and the rest will be very close to the replacement time so that mismatched injectors can cause engine imbalance.

What causes a skid steer engine to overheat?

The major causes are most likely a clogged radiator (quite common in landscaping), a broken-down water pump, or an unoperative fan belt. Before everything else, always verify the level of liquid in the radiator as well as the cleanliness of its “fins”.

Is it a good decision to rebuild a skid steer engine?

Yes, if the hydraulics and chassis of the machine are in good condition. It is a lot cheaper to rebuild an engine with a good quality kit than buying a new machine or a “crate” engine.

Final Thoughts on Skid Steer Engine Timing

It is not just keeping time with a calendar, but more like you hearing your machine that help you in timing your engine part replacements very well.

With the combination of data from your hour meter and the physical signs of wear, the reliability of your skid steer as an asset can be assured for years to come.

Most importantly, high-quality replacement parts are what you should not hesitate to invest in for your engine’s future, especially when you discover that a part is getting worn out.