The Ultimate Guide to Using the TYPHON Skid Steer Bull Dozer for Construction Pros in the USA

One of the major concerns that professionals in the rapidly and ever-changing construction industry of the USA are looking for is the kind of machinery that can perform well, is adaptable and costs less or gives value for money and their search ends when they find Typhon Skid Steer Bull Dozer along with other relative attachments.

The TYPHON Skid Steer Bull Dozer is a major winner in the arena of jobsite productivity because of its strong nature and great versatility. The in-depth guide shows how the TYPHON Skid Steer Bull Dozer is the power tool that American construction pros can use to increase

productivity, simplify project workflows, and have command over the most demanding situations of their sites. No matter if you are a contractor, a fleet manager, or an onsite operator, this blog will provide you with understanding and practical tactics to make use of every leverage that the TYPHON offers.

Why the TYPHON Skid Steer Bull Dozer is a Game Changer?

The TYPHON Skid Steer Bull Dozer is the most prominent one out of a dynamic attachment pack that can convert your skid steer loader into a multi-functional earthmoving powerhouse. Construction professionals in the USA invest in ways that can maximize their returns while they find means of finishing their projects as fast as possible.

The TYPHON meets these demands with durable materials, operator-centric features, and compatibility across major loader models. Its advanced hydraulic controls, reinforced blade, and modular mounting system provide broad functionality that covers everything from initial grading to final site clean-up, thus creating the competitive edge for forward-thinking builders.

The TYPHON Skid Steer Bull Dozer is equipped with a reinforced dozer blade that is designed for both hard-packed soil and loose debris, thus making the blade more durable through the intensive cycles of construction.

Its adjustable hydraulic controls allow for precise blade angles and depth adjustment, thus giving the operator the ability to fine-tune the performance according to the site conditions.

Moreover, by being compatible with the leading skid steer brands, a user can easily install the device, and if there is a need for a quick change-out, it can be done within a short time, thus the operators are not interrupted by the expensive delays of the tasks that are going on.

Key Applications: How Construction Pros Use the TYPHON Skid Steer Bull Dozer

Major American construction projects require that the equipment used should be versatile thus the machines can be used across many tasks that would reduce the fleet cost and increase the overall effectiveness.

- The TYPHON Bull Dozer releases the distinct advantages in jobsite preparation, material grading, road construction, trench backfilling, and debris clearing.

- The bulldozer blade (or the end) is a very efficient means of stripping topsoil, leveling uneven ground for slab foundations, and making accurate drainage channels for site protection.

- During road and highway construction, operators benefit immensely from the use of the TYPHON tough blade to do sub-base grading, shoulder maintenance, and roadside debris management.

- Upon completion of the trenching, the attachment is most effective during backfill and compaction processes that facilitate safe, fast coverage of utilities while at the same time, site accessibility is maintained.

Choosing Skid Steer Bull Dozer – Productivity Advantages for U.S. Construction Companies

The challenge to keep up with the rapid pace of the U.S. construction industry makes every minute saving money that is turned into profit. Prominent time-saving and cross-cutting features in the TYPHON Skid Steer Bull Dozer are what draw the attention of the American worksite’s demands. It accomplishes this goal through its one-all-in approach, which eliminates the need for frequent machine changes, thus raising the operational flow and safety metrics.

- With the help of quick-connect couplers, tool-free installation can be achieved by the operators who are able to switch their rigs from digging to grading work in a matter of minutes.

- The use of advanced blade control tools implies that fewer passes will be necessary in order to move and redistribute material thus less fuel will be consumed and the site vehicles will be subjected to less wear.

- There are built-in operator safety technologies such as anti-slip blade design, reinforced side shields, and intuitive in-cab controls that guarantee fewer risks of situations leading to accidents and injuries during periods of high demand.

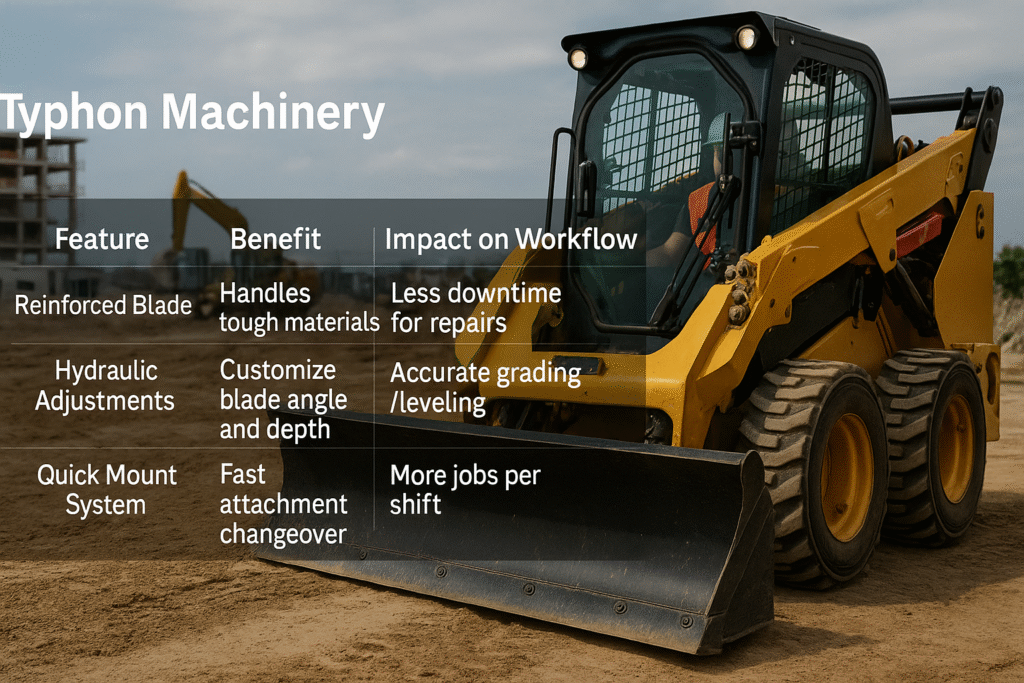

Table: Skid Steer Bull Dozer Features and Benefits

| Feature | Benefit | Impact on Workflow |

| Reinforced Blade | Handles tough materials | Less downtime for repairs |

| Hydraulic Adjustments | Customize blade angle and depth | Accurate grading/leveling |

| Quick Mount System | Fast attachment changeover | More jobs per shift |

Essential Maintenance Tips for Longevity

Just like any other expensive/high-value attachment, the TYPHON Bull Dozer needs regular maintenance, if you want to keep it in a good working condition, in the long run, and get back your money through the long-term use. US contractors who have made it their habit to perform periodical preventive maintenance report less breakdowns, longer intervals between services, and fewer warranty-related issues.

- Always check the hydraulic fluid levels and if there is a leak in the system, be sure that it is fixed quickly so that component wear due to low fluid and sudden breakdowns will be avoided.

- Make the most of the blade edge by not letting the buildup of debris be too much and after heavy use, check it for breaks and distortions.

- Do not forget to apply lubricant to all the moving parts and always check the tightness of the attachment couplers as the vibration caused by hard material grading can gradually loosen the fasteners.

Skid Steer Loader Compatibility and Integration

- The TYPHON Skid Steer Bull Dozer was designed for smooth integration with a variety of North American brands of skid steer loaders. The universal mount and hydraulic plug system facilitate easy set-up and efficient power transfer.

- As the universal mounting plate of the attachment is the one, which will be time-saving and less of a guessing game if one will be retrofitting onto older or non-standard loaders.

- Hydraulic quick-couplers are manufactured to be compatible with both American and International connector standards, which is vital for fleets with mixed equipment sources.

- With the adjustable settings for mounting height and angle built into the device help to offset differences in the structures of the loader arm geometries thus relieving the stress on both the attachment and the base machine.

Operating the TYPHON Bull Dozer: Step-by-Step Guide

It is important that the Bull Dozer blade is used properly so that the highest output is attained with minimum wear and tear to the machine. New training as well as abiding by the recommended operation sequences will assure that the US operators will get the highest value from each workday.

- First, make sure that you employ the manufacturer’s locking coupler when attaching the TYPHON Bull Dozer to the skid steer, also verify the hydraulic connections through a double-check before switching on the machine.

- Start with slow-speed runs so that one gets a proper understanding of material movement, and gradually up the blade pressure as per the requirement for a continuous leveling.

- Turn the on-board blade angle adjustments to help with windrow creation or side-cast grading the design supports both fine finish work and heavy soil pushing.

Advanced Tips for Maximizing ROI with the TYPHON Bull Dozer

- By going an extra mile to push ROI, top construction professionals implement advanced attachment tactics and timely technology upgrades tailored for American market and regulatory trends.

- Please consider monthly operator training sessions as a way to keep up not only new but also experienced staff members with the latest performance and safety aspects of the attachment.

- Install GPS machine control systems onto the Bull Dozer as a smart technology add-on which helps in faster and more accurate site grading and mapping without heavy capital investments.

- Stay on top of your equipment usage metrics and predictive wear reports to coordinate your service intervals with real-world conditions thus you are reducing the risk of unexpected downtime and fleet management KPIs alignment.

Safety Protocols for Responsible Bull Dozer Use

It is definitely not secondary to safety to have a professional construction site where security measures are very well observed. Safety features present in the TYPHON together with the observance of strict operating safety rules contribute a lot in creating a safety culture that is characterized by risk reduction and reliability of the workflow.

- Make sure that all site operators are fully acquainted with the equipment’s safety manual, which should also contain the specification of the safety load limits and the maximum speed recommendations.

- Besides installing cab protection systems, assure that they are in good condition through frequent testing, most importantly when the working environmental conditions are close to edge areas or high places.

- During low-light or public-adjacent works, employ very noticeable signalling and passive safety means like blade reflectors and warning beacons for the safety of workers and people nearby.

Trending FAQs: TYPHON Skid Steer Bull Dozer

Here are seven of the most asked, trending questions about the TYPHON Bull Dozer and similar attachments—gathered from the most relevant online results front page:

Compared with regular dozer blades, what are the features of the TYPHON Skid Steer Bull Dozer that make it different?

Reinforced, multi-angle hydraulic controls along with top-notch build quality are the main reasons that the TYPHON is more durable and accurate than typical aftermarket blades.

Does the TYPHON Skid Steer Bull Dozer work with all the brands of skid steers?

Yes, since it has a universal mounting plate and standardized hydraulic fittings which make it compatible with a wide range of the U.S. skid steer models.

Is it possible to use the Bull Dozer attachment for snow removal aside from grading?

Sure thing. The TYPHON’s movable blade and sturdy build make it a great solution for snow removal, ground leveling, trench backfilling, and litter clearing.

How do you keep the TYPHON Skid Steer Bull Dozer in good condition to extend its life span?

Conducting regular checks on the hydraulic lines, ensuring the blade is sharp, the mount hardware is torqued, and lubricating the pivot points—are the same seasonal practices as those suggested for your skid steer loaders that should be followed.

Which are the safety features incorporated in the TYPHON Bull Dozer?

The extremely safe operator environment facilitated by the anti-slip blade surfaces, the heavy-duty blade sides, and the ergonomic in-cab control layouts remains the main operator safety even in tough or unpredictable environments.

In what ways does the utilization of the Bull Dozer attachment lead to jobsite efficiency enhancement?

The single device, a.i. the Bull Dozer attachment, merges multiple jobs one into another, i.e. grading, material movement, clean-up, thus the machine idle time and operator effort are reduced drastically.

What are the prime utilization scenarios of the TYPHON Skid Steer Bull Dozer in the USA?

Basically, it can be used for site grading/trenching foundation prep/road shoulder maintenance/post-storm clean-up—any situation where rugged, precise earthmoving would be of great help.

Conclusion: Empower Your Projects with the TYPHON Skid Steer Bull Dozer

The TYPHON Skid Steer Bull Dozer in an excellent tool which is worth every penny for the long-term American construction professionals who are determined to keep up jobsite efficiency and still be future-proof. It is a great combination of features such as build quality, functional engineering, and easy operation that, apart from dollars, brings extra value with the terms of uptime, project quality, and operator safety.

You will make use of each competitive advantage offered by TYPHON, if you observe the good practices of maintenance, operation, and compatibility that are shown above. Keep up with the news from reliable sources like https://steerskid.com/, where leaders in construction look for dependable guides, trend analysis, and actionable jobsite insights.

Thank you for your sharing. I am worried that I lack creative ideas. It is your article that makes me full of hope. Thank you. But, I have a question, can you help me? https://www.binance.info/register?ref=IXBIAFVY

https://t.me/officials_pokerdom/3902